-

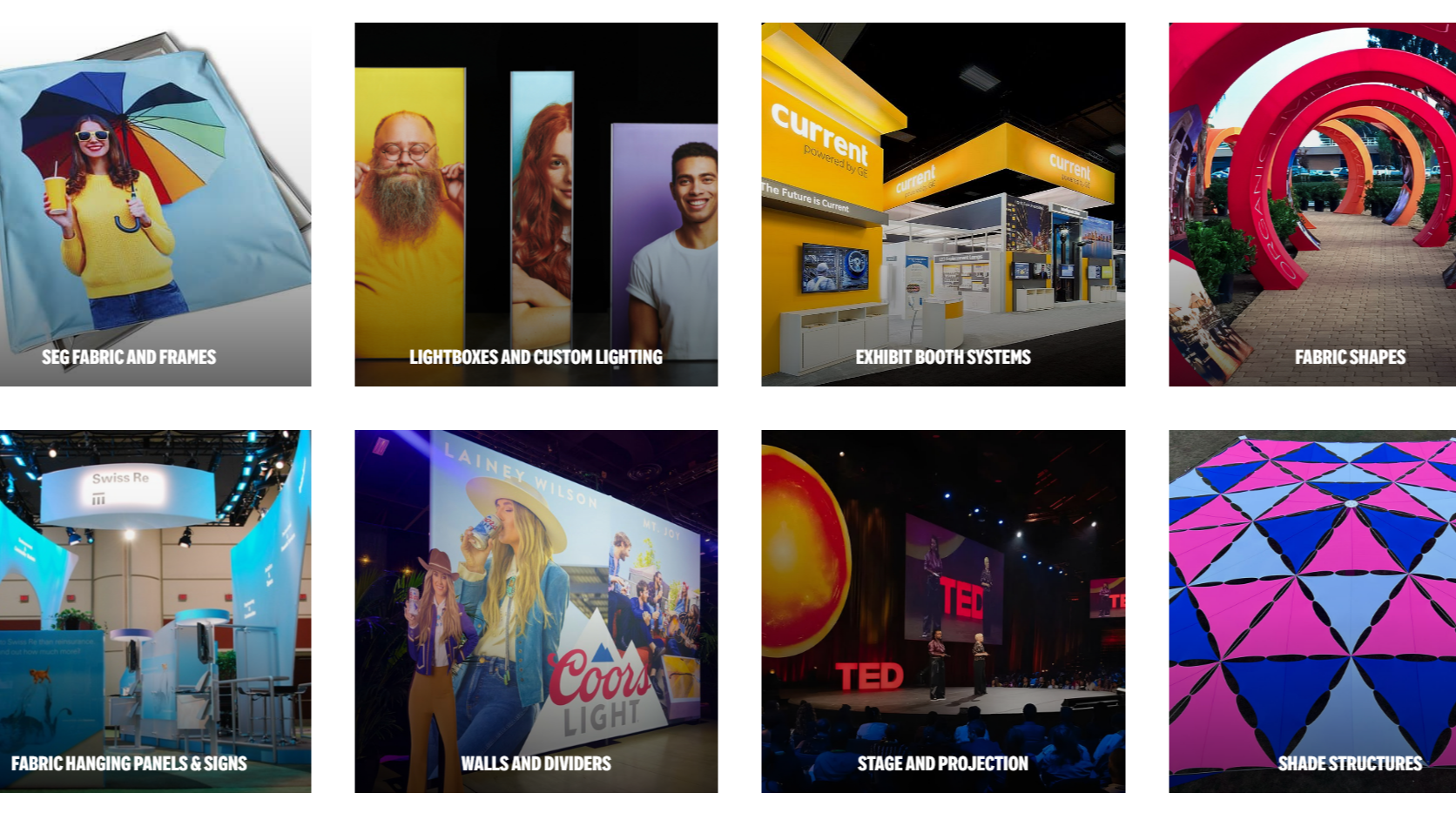

Fabric design

-

Tailoring

MOSS

-

Advertising Fabric

-

Light Box

-

Easy Pull-ups

-

Large cloth rolls

-

Big surplus material

-

Small Remainder

-

Tail Material

-

Customer Profile

MOSS is committed to the overall programme design of environmentally friendly large-scale cloth-decorated structural exhibition and display appliances.In 2017, MOSS Exhibition Systems Co., Ltd. was established by a joint venture between MOSS (USA) and China Lingtong Exhibition Systems Ltd. in MOSS, which is mainly engaged in providing environmentally friendly large-scale cloth-decorated structural exhibition and display appliances and overall programme design. Continuing the road of green environmental protection, we bring the comprehensive design concept and one-stop fabric decoration frame structure into the Chinese exhibition market.

-

Informatics Challenges

1.Products: customised advertising fabrics, light boxes, building facades, exhibitions, easy-openings and other occasions for use. Most of the business is highly customised large-scale products, customised product management claims;

2.Personalised design management by order; advertising art must be customised, produced by order, rarely flip orders;

3.Process standardisation claims: customer demand -> art design -> production design -> final offer -> sales order -> production plan -> purchase by order or use of stock preparation -> production and shipment by order.

4.Personalised management of tailoring production;

5.Remainder and tail material management.

-

Solutions

1.Design and quotation by order: design by order through professional design software, generate cost estimate and external quotation;

2.After the order is closed, according to the pre-design, and at the same time consider the inventory of all kinds of surplus materials, the principle of maximising the use of surplus materials, to generate production and collateral plan;

3.Cutting production according to the design:

(1) According to the output of the production plan for the amount of collateral, usually a large roll of fabric, or specify the use of a surplus material; large rolls of collateral operations for the first to lead and then return;

(2) Unroll fabric rolls + cut pieces, according to the type of product, one is cut lengthwise, the other is to cut a specific length and width of the rectangle; the cutting surface requires special treatment, are cut with a cutting machine;

(3) Large rolls are re-stocked; remnants are stocked (with the possibility of re-rolling); those below a certain size are regarded as scrap and managed as scraps;

(4) Cut fabrics, airbrush for spray painting, there may be multi-layer spray painting; extra-large products to be sprayed several times;

(5) The end of spray painting, according to the different needs of the finished product, directly into the packaging, or to do the second splicing (made into a closed surface, or made into a large plane), and may be on the tension machine;

(6) Quality inspection of finished products;

(7) Part of the product for outsourcing production, sewing hardware (large advertising, purely manual operation) or assembly (easy pull-up, light boxes)

(8) Packaging; according to different types of products, the longitudinal cut products are re-rolled by machine; rectangular products are stacked and packaged; super-large products are folded manually;

(9) Finished product quality inspection, packing, paste inside and outside the box bar code, box list, delivery;

4.Various types of large residual material, small residual material inventory management, tail material processing and financial cost adjustment.